Repairing

Drawers

Over time, wooden drawers that

are

well-used will begin to show wear

and tear. Boards can warp and lose their fit, guides slide

poorly along

worn runners, and the frame of your piece may become damaged.

With

prompt attention, most drawers can be fixed and returned to use,

enabling them to glide open smoothly, holding everything from

sweaters

to silverware. Here are some of the most common problems with

draws:

Loose

Joints

Drawer frame construction is

similar

to chair construction. Dovetail

joints (wedge-shaped openings or dovetails that hold matching

pins cut

in the joining piece) are used in old or expensive furniture.

Butt

joints (joining pieces simply butted together either face to

face, edge

to edge, or face to edge with no integral fastener) are glued

and held

with corrugated nails in newer furniture.

Dovetail joints seldom separate;

if

they do, adhesive can be forced into the

loose joint which can then be tapped together with a hammer.

Butt

joints are

another problem. To tighten a loose butt joint, The joint should

be

glued and tapped together as firmly as possible with a hammer

then

clamped firmly until

the glue is dry. If this method fails to provide enough

strength,, it

may be possible to nail the

joint through the face of the drawer. The nail heads being

countersunk,

and the holes finished with wood filler.

Binding

Problems with drawer frames are

usually the cause of sticking and

binding drawers. When a drawer sticks, it's jerked to get it

open and

slammed closed. This causes the joints in the frame to separate.

First,

the joints are checked to se that they are tight, then the

drawer

guides are lubricated and

the top and bottom edges of the sides with stick lubricant, wax

from a

candle, paraffin, or silicone spray. Petroleum based

lubricant is not used;

oil will collect dirt and dust and cause more problems than the

binding.

If lubrication doesn't solve the

problem, we carefully sand down the

binding points. Removing only as much wood as necessary, and

seal the

raw

wood with shellac to prevent future swelling. If sanding doesn't

eliminate binding, the drawer's runners and guides are

examined.

Worn

Guides

and Runners

Drawers are built with wood or

metal

runners and move back and forth on

guides or tracks. In old furniture, the runners are parallel

pieces of

wood fastened to the drawer bottom, and the guides are strips of

wood

across the frame. Sometimes the runners or guides are missing;

sometimes they're split, warped, or badly worn. Rough guides or

runners

can cause the drawer to bind and can eventually damage the

frame.

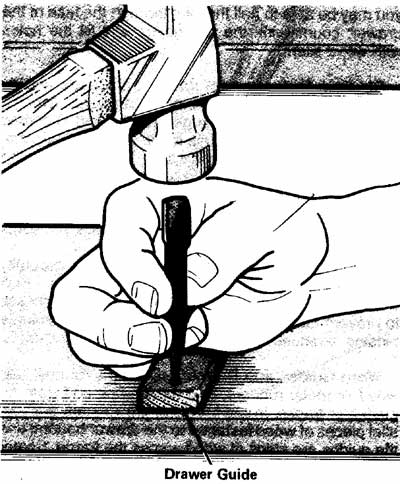

If the drawer guide is missing,

metal

guides are installed (or duplicate wooden ones on antique

furniture),

metal guides are available in

several lengths. If a wood

drawer guide is rough, it is smoothed carefully with sandpaper

or a

rasp, or

-- as a last resort -- a block plane. If the drawer still binds,

the guide is removed completely. A hacksaw blade is broken in

half and

one end of

it wrapped with electricians' tape. The guide is cut out with

short strokes of the saw blade.

After removing the old guide, it

should be possible to install metal guides, or a new wooden

guide that

is the same size

as the old one. Hardwood is used to make the guide; softwood

wears too

quickly. The new guide is glued into position, and secured it

with

nails. The nail heads are countersunk so they won't interfere

with the

drawer's

operation.

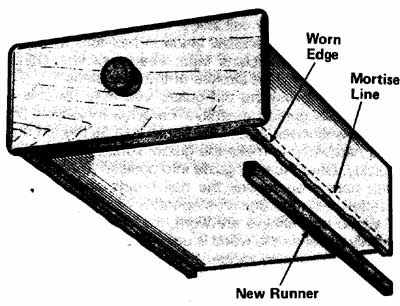

When the runners are worn, the

drawer

moves unevenly because the wood

is uneven. To replace a worn runner, we plane and rabbet the

worn edge

to

form an even, smoothly mortised strip along the drawer edge. A

new

thin strip of hardwood is glued into each mortised runner edge,

building it up

to its original height. The runners are secured with small

nails, and

the nails countersunk so that they won't interfere with the

drawer's

operation.

If the drawer frame has a wood

kicker

above the sides and the kicker is

worn, it is smoothed and add a new hardwood strip added to build

it up

again. The same procedure used to replace worn runners is

followed.

Split

Drawer Fronts

Split drawer fronts are usually

the

result of broken ormissing drawer guides.

First we replace broken or missing drawer guides. Second, we

repair the

split with glue forced

into the break, wiping away any excess glue, and lightly clamp

the

edges

with a strap clamp. Only light pressure is used; too much

pressure will

buckle the wood at the split.

Split

Drawer

Bottoms

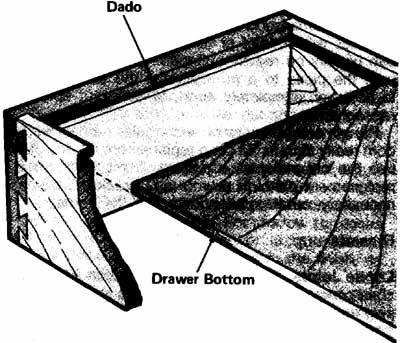

Drawer bottoms are not fastened

into

the drawer sides and ends; the

bottom panel fits loosely into dadoes (slots cut into the face

or end

of a piece of wood) in the sides. This permits expansion and

contraction of the wood and prevents the joints from

cracking.

To replace a drawer bottom, we

remove

one end of the drawer and slide the

bottom panel out, replacing it with a new plywood or hardboard

panel

cut

to fit. Some drawer bottoms are lightly tacked to a piece of

molding

nailed to the inside edges of the sides and back, and some

drawer

bottoms are set on triangular glue blocks. These fasteners or

braces are removed before disassembling the drawer. If the piece

of

furniture is an

antique, the drawers were probably hand-fashioned. These drawers

should

not be repaired with plywood or hardboard.

Warped Boards

Table leaves and other flat

parts can

warp unless they're properly

sealed, and years of uneven humidity can leave them severely

cupped. In

most cases, unwarping them isn't too difficult.

To unwarp a board, its better if

work

is done in the summer. The traditional cure is exposure to

wet grass and hot sun. A grassy area is watered thoroughly, and

set the

board curved side up on the wet grass. As the dry side of the

board

absorbs moisture from the grass, the moist side -- the convex

side --

is dried out by the sun, and the board unwarps. Unless the warp

is

caused by stress in the wood, the board should straighten out

within a

day.

When the board has

straightened out,

it is clamped between two straight

boards so that it will dry evenly. Before replacing it in the

piece of

furniture, the unfinished side is sealed with shellac to prevent

it

from

warping again.