REPAIRING

A

CHAIR SEAT

Probrably the most important

part of

a chair is where you sit. A wooden chair seat that is split or

needs to

be replaced will be an obvious spot to perform repairs.

Split

Seats

Split chair seats can be

repaired

with a series of 3mm dowels (wooden pegs) along the break and

reinforced with metal mending plates. The seat must be

completely

removed for doweling.

Drill holes for the dowels in

each

side of the broken seat, about 25mm deep (or as deep as

possible) and

spaced about 4 to 6 inches apart. A doweling jig is used,

clamped to

the broken seat, to drill the dowel holes. We cut and score each

dowel

, 6mm less than the total length of the dowel holes.

Glue is applied to one end of

each

dowel, and inserted into the holes along one side of the broken

seat;

then glue is applied to the protruding dowel ends and to the

broken

edge, the two parts are then joined. The pieces of the

seat are

tapped together with a rubber or wooden mallet, and any excess

glue

wiped off. The glued seat lightly clamped and left to dry for at

least

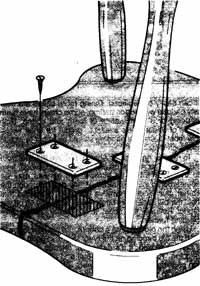

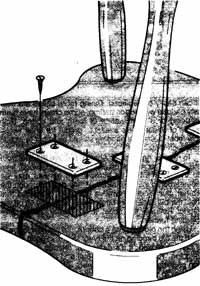

two days. For extra strength, metal mending plates can be added

to span

the break, like the one above -- four plates is adequate.

Finally, the

chair is reassembled .

Inserting Chair Seats

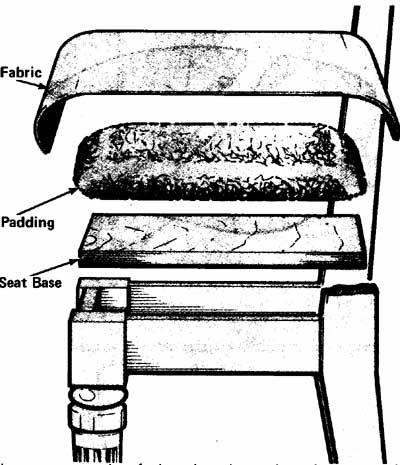

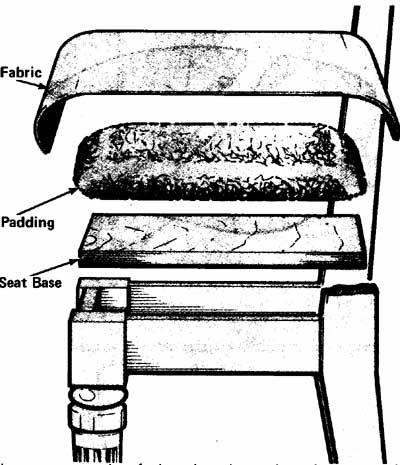

Chair seats set in or on frames

are

usually boards or plywood covered with padding and cloth. These

seats

seldom split, but when they do the simplest solution is to

replace the

seat with a new piece of plywood -- 8mm thickness is best. If

8mm

plywood won't fit properly after the padding has been added, 6mm

plywood can be used, but anything less than this will not

provide the

needed support. The old chair seat is used as a pattern to

cut

out the new one.

Padded chair seats are usually

held

to the frame with screws driven through glue blocks. all

fasteners are

removed, and replaced the same way to hold the new chair

seat.

If the upholstery on insert

seats is

worn or damaged, it can easily be replaced as interior chairs

are

usually padded with cotton batting. Some chairs have foam

padding or a

combination of foam and cotton. Both types of padding are

available

precut for chair seats. For most chairs, the padding should be

about

15mm to 25mm thick.

To recover an insert chair seat,

it

must be removed from the chair. The seat is usually a piece of

plywood,

held to the chair frame by screws; the screws may be

counterbored into

the frame or may go up through the corner glue blocks. The tacks

or

staples that hold the old upholstery fabric to the seat are

removed,

and the fabric is lifted off. The chair is refinished, if

necessary,

before proceeding further.

Using the old fabric as a

pattern,

new fabric is cut to fit. If the old padding on the chair seat

is in

good shape, it can be reused; if it's damaged, it is replaced

with new

padding. It may be possible to fluff and smooth old cotton

padding; if

it's badly flattened, a layer of foam padding may be added to

build the

seat cushion up to 15 to 25mm.

The new fabric is laid flat,

wrong

side up, and center the padded seat on it upside down. The edges

of the

fabric are folded up over the seat, stretching it firmly onto

the

plywood; the fabric is taped firmly down with masking

tape.

Starting at the center of one side, the fabric is folded under

and

attached to the seat with a staple gun using heavy-duty staples.

If the

new fabric is very heavy, flathead upholstery tacks will be more

secure. Staples or tacks are set 25mm to 35mm apart along the

side of

the seat.

When the first side is

completely

attached, the fabric is restretched; then stapled or

tacked to

the opposite side. The seat is turned over and the padding is

smoothed

out, making sure the fabric is straight, with no wrinkles. Then

the

seat is turned over again, and the other two sides fastened. At

the

corners, the fabric is folded in to miter it neatly; if

necessary, each

layer is stapled or tacked separately. Finally, a scrap piece of

the

new fabric is stapled under the seat, in case repairs are

necessary in

the future. The chair seat is replaced in the frame, and

resecured. All

the screws are replaced, and tightened firmly.