Introduction

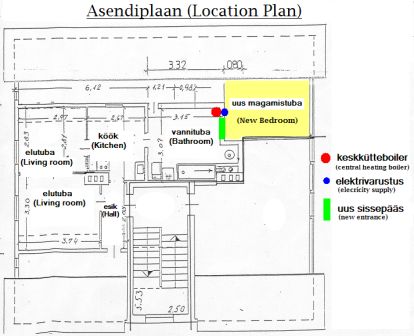

The project is to convert the remaining loft space,

adjacent to a 4th floor loft conversion apartment situated

within the roof space in a 1930,s traditional 3 floored

detached house. Although the free space to be converted is

small (approx. 6 square meters) and the roof angle

virtually cuts the total volume in half, effectively

cutting out nearly 50 percent of the floor space if to be

used by adults (head height reduced by roof slope). It

could be a practical kid’s bedroom space owing to children

needing less room height and the very low area could be

employed as a practical storage space for toys etc.

Proposed

Project (Childs Bedroom) Feasibility

The entrance door leads from the bathroom of the

existing apartment, there is sufficient space within the

bathroom to partition a corridor from the new room to the

main living area, effectively bypassing the existing

bathroom for practical reasons. The existing central

heating system consists of a gas combination boiler which

is conveniently situated adjacent to the proposed bedroom,

simplifying the work involved with the extension to the

central heating circuit (of course, the capacity of the

existing central heating system should be quantified

before any work commences to check that it is capable of

coping with the extra radiator. Due to the new space being

a bedroom, unlike a kitchen the expected electricity load

will be minimal so a spur (electricity line) can be taken

from an existing circuit on the system. It is not

necessary to create a dedicated circuit from the main

consumer unit with its own dedicated trip switch.

Initial Inspection

The most important thing to establish is

the structural stability of the existing structure.

Because any work carried out within a previously

uninhabited structure will cause new loads, stresses &

vibration, it is vitally important to determine the

structural stability and hence, the ability of the

existing structure to cope with not only the proposed

final purpose, but also the stresses caused during the

work.

There a many factors that will effect this ability, old

structures move over time and eventually settle into

equilibrium, the stability is finely balanced, structural

beams and columns weaken with time, not just age but other

factors such as dry/wet rot, fungal and insect

infestation, degradation of metallic fixings (nails/screws

etc.). A thorough inspection must be undertaken by a

qualified professional.

I am a UK degree qualified building engineer and

from my 20 years of experience I can tell many 'horror'

stories of situations where this first 'professional

inspection' has been overlooked, leading to not just large

financial loss but also danger to life (it’s a long fall

from the second or third floor) if you don’t establish a

safe working environment to start with.

For a thorough inspection to be undertaken, it is

necessary to remove anything that covers important parts

of the structure, this includes old insulation, wallpaper,

floorboards etc. so that any hidden problems can be

confronted.

With this loft space there was very little evidence

of dry/wet rot or fungus because the structure was

waterproof and well ventilated, there was however an

infestation of wood boring beetles {woodworm)

Woodworm Treatment

Because

of the woodworm infestation, it was necessary to remove

all the existing coverings to the structural timber in

order to expose all the infected areas.

The type of woodworm was identified as the Common

Furniture Beetle (Anobium punctatum). In most cases

treatment of Common Furniture Beetle is fairly

straightforward. Any structurally-weakened timber should

be removed and replaced with pre-treated timber. All

surfaces of the affected timber should then be treated

with Woodworm Treatment applied by brush or spray.

All the infected timber was cut out, first ensuring

that the remaining ‘good’ timber would be of adequate size

and strength to perform its intended structural purpose.

The depth of infection was up to 25mm in the worst areas,

leading to the requirement for one of the vertical columns

to be reinforced before the bad wood was removed and

remaining good wood then treated.

As can be seen in the following photographs,the worst

infected wood was removed gently by scraping it away, the

remaining good wood was then reinforced with two

(60mm by 150mm) pine columns that had been pre-treated

againt woodworm. Thes were attatched securely to either

side od the existing column, with numerous steel bolts,

penetrating completely through the ‘heart’ of the good

remaining timber, effectively joining all the timber

together to act as one structural column. This provided

adequate support to the beam resting above before the

remaining infected timber could be removed and the

remaining good timber treated.

There are many solutions available for treating

woodworm but the basic application method is as follows.

Firstly however, it must be understood that these

chemicals are harmful to health and sufficient protection

must be provided against inhalation and contact with the

skin. The financial cost of this protective equipment

makes it impractical for use on a single job. It is more

economical to employ a specialist to do the job, you get

the advantage of a warranty if the treatment is

unsuccessful and also avoid risk to your health from what

is not a ‘pleasant’ job.

8mm diameter holes are

drilled in and around the infected areas, vertically in

beams and as close as possible to vertical in columns, to

a depth of about 40-50mm, approximately 100mm apart. The

solution was prepared according to the manufacturers

instruction and poured in the holes. The total surface

area of the infected wood was thoroughly sprayed with the

solution. The work is then stopped until the solution has

had time to do its job, according to the manufacturers

instructions.

Repair/replace

Damaged Structural Timber

During

the life of the building, various parts of the structural

timber have become damaged or removed for various regions.

Where replacement is not possible for practical reasons,

if structural stability remains adequate, then

reinforcement is added to prevent further damage.

As shown in the above photographs, splits in

vertical timbers are prevented from getting worse by

clamping them together with the aid of metal bolts (ringed

in red on photograph). Other damaged areas are repaired

with fresh timber, pretreated against woodworm.

Weatherproof External Wall & Ceiling

As The entire roof covering was replaced only six months

before with metal roofing cladding and lined beneath with

moisture proof paper, there is no evidence of damp on the

underside even though there has been much rain since, so

it is safe to assume that it is weatherproof and work to

insulate the underside can proceed.

However, as can be seen from the photographs below,

daylight can be seen through gaps in the external cladding

of the external wall. This wall is exposed so its

resistance to the wind and rain needs to be improved

before the insulation can be installed.

Moisture proof paper was applied to the wall, with any

joins overlapped and taped. Boards were then fixed over

the gaps in the external cladding.

Wind resistant board was then secured over the top and any

remaining gaps were sealed with a foam filler that is

suitable to withstand freezing temperatures because it is

located on the outside of where the insulation will be

placed.

Two layers of mm thick insulation matting were then

applied to the wall, supported with a string harness so as

to prevent them from slipping out of position and leaving

gaps. The string used was synthetic so as not to rot and

break over time, letting the matting slip.

The same system was used to insulate the ceiling under the

new roof covering, creating a completely weather proof,

insulated external shell to the new bedroom. As the area

below the floor is an occupied space and heat travels

upwards, it is pointless to insulate against heat loss.

Install Floor

Support Structure

When the interior had effectively been protected against

water leaks and dramatic changes in temperature and

humidity, the new floor could be started. The

existing beams (third floor ceiling/attic floor)were found

to be of sufficient size and adequate condition to support

the proposed floor structure for the new bedroom,

consisting of pine interlocking floorboards, resting on

pine floor support beams. These floor support beams were

supported off the existing attic floor structure and fixed

securely as indicated in the photographs below. These

floor support beams provide two functions. They

effectively raise the finished floor level to match the

level of the floor in the existing attic accommodation, it

also provides the space under the new floor,

allowing ventilation which will reduce the chances of

problems like rotting and fungus.

Floorboards were then selected of

adequate length and thickness to span the gaps between the

floor beams and not result in any of the board ends being

unsupported at a joint by a support beam, resulting in a

finished floor being of sufficient strength and stability

for its purpose. The boards were then laid with the joints

staggered to form a uniform pattern.

It is important to store the boards in a place of similar

humidity and temperature to where they are going to be

fitted, for some time. This is because they are usually

stored outside at the suppliers, if they are fitted

straight away, they can shrink or expand because the

moisture content will change. This will result in buckling

or gaps between the boards in the finished floor.

Laying The

Floor

Because the opposite walls were not parallel, as is

normally the case, it is important to start from the

center of the room and work out towards the edges, this

results in the difference being minimized when the floor

is completed. If you start from one side, the difference

will be very obvious by the time you get to the other

side. The boards are nailed through above the tongue at a

45 degree angle and punched home with a nail punch. The

boards then slot together smoothly and are hidden from

view in the finished floor. The last boards are then cut

to fit 5mm from the walls to allow for any expansion. This

gap will be hidden when the skirting boards are fitted to

the bottom of the walls.

Apply Boarding

To Walls And Ceiling

6mm particle board was chosen in favor of

plasterboard because of its strength for supporting

shelves and other fittings. This was cut to the correct

size and screwed to the ceiling joists and structural

beams & columns on the walls. All edges of the boards

require fixing so additional timber was added where

required, attached to the structural supports.

A support frame for the boarding was fitted around the

‘Velux’ window, making sure that all voids were filled

with insulation wool.

The gaps where the boards join were then filled with

flexible filler and the surface of the walls and ceiling

smoothed and prepared to receive a decorative paint

finish.

Decoration

The walls & ceiling were then painted with one

coat of base paint and two coats of top coat. The exposed

woodwork was then given a final sanding and given a finish

of linseed oil.

The floor, left until last was then sanded smooth, the

gaps between the floorboards and central beam were filled

with flexible parquet filler and then finished with

linseed oil.

Finally, the bedroom was wired up for lighting and a

radiator fitted with pipework connected to the existing

system.